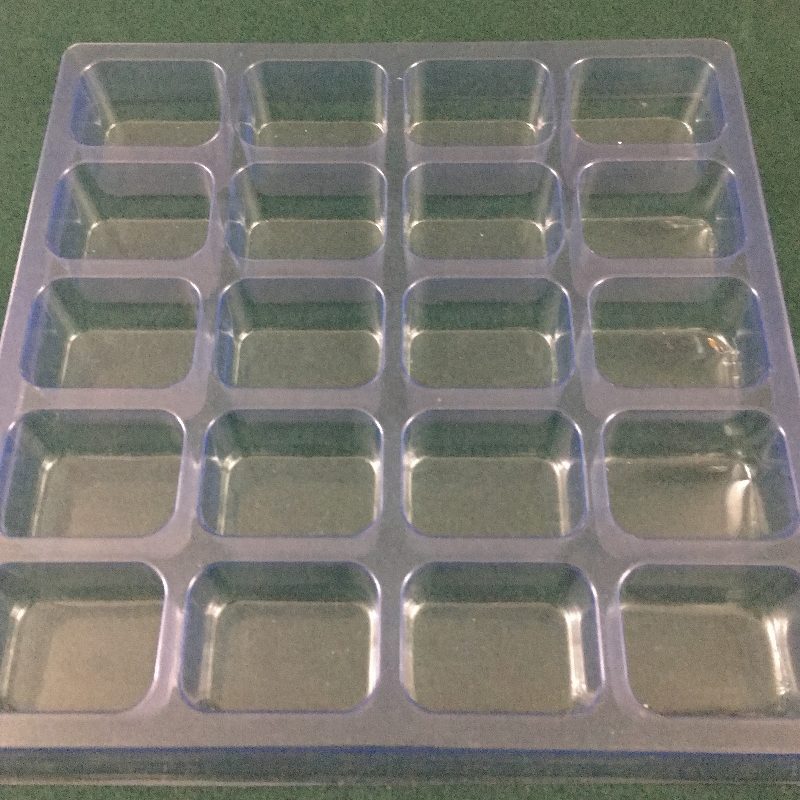

Machine Shop Component Parts Shipping Trays

- Trays fit standard 12″ x 12″ boxes

- Over 40 different cavity configurations

- Plastic shipping trays nest easily for stacking stability

- Trays for very small machined parts

- Cavities sizes from .210″ x .325″

- Special cover holds small parts in cavities

- Cylindrical Cavity Trays

- For CNC & Swiss Machine Parts

- Stacking Trays

- White Paper Trays for Cylindrical Parts

12 x 12 Reusable Shipping Trays

43 unique cavity trays fit in one box size.

The 12″ X 12″ Lineup of Trays has a wide variety of cavity sizes; including narrow cavities. All trays in this category are made to fit a standard 12″ X 12″ box. One box can hold many different component parts. Trays are stackable. Link to cavity sizes at above photo. Bookmark tray catalog for future reference. Trays are sorted by cavity shape, then in order of cavity size smallest to largest.

Cylindrical Parts Shipping Trays

Swiss Machining Reusable Component Parts Trays

Cylindrical Cavity Trays can be a good stock option for Swiss machined parts. These trays are built with narrow pockets which prevent side to side movement. View the cavity Size Chart and product pages.

Custom Machined Parts Handling & Shipping Trays

Custom Thermoformed Tray Design Guide shows common materials, design features and general guidelines.

Custom trays are available for applications which require special cavity shapes, for fragile items, and for automation applications. Low tooling cost makes a custom cavity option viable with low volumes. For more information on custom trays view the custom tray design guide(link above) or Contact Us to review your requirements with a packaging consultant.

Medical Component Parts Trays

Stock and Custom Medical Tray Options

For medical component machined parts, we offer the same trays in PETG material. PETG is often used in Plastic Medical Trays & Packaging. If medical machined parts are used in a clean-room environment, double bagging of trays is available on run to order items. More information on Medical Tray Applications, please visit Plastic Medical Trays, Bins & Packaging.

WHY Thermoformed Cavity Trays for Machined Part Protection?

In industries like military, medical, automotive, aerospace, and OEM manufacturing, the integrity of machined parts is non-negotiable. Lathed and milled components, often precision-engineered and costly, are vulnerable to damage during handling and transport. Scratches, dents, and abrasions can compromise functionality and lead to expensive replacements. This is where thermoformed cavity trays step in, offering a reliable solution for part protection.

These trays are meticulously designed to cradle each component, preventing contact and minimizing the risk of damage.

Customized Protection: Whether you opt for readily available, off-the-shelf trays or require custom vacuum formed trays, the goal is the same: to provide a secure and protective environment for your machined parts. – Off-the-shelf trays offer a quick and cost-effective solution for standard-sized components. – Custom vacuum formed trays are ideal for uniquely shaped or highly sensitive parts, allowing for a perfect fit and maximum protection.

Enhanced Efficiency: Cavity trays organize parts, simplifying inventory management and streamlining assembly processes. They facilitate efficient handling and transport, reducing the risk of human error and damage. Industries Benefiting from Thermoformed Part Protection:

Contact ECP Tray for assistance in any of the areas noted below:

– Machined part protection – Thermoformed cavity trays – Vacuum formed trays – Part protection trays – Lathed part protection – Milled part protection – Protective packaging for machined parts – Off the shelf cavity trays – OEM part protection – Precision part protection

SUMMARY: By utilizing thermoformed cavity trays, you can ensure that your machined parts arrive at their destination in pristine condition, maintaining quality and minimizing costly replacements.

Component Parts Common Tray Materials:

- PVC BVRC Spec Sheet and PVC AS H1X Spec Sheet

- PETG Clear and PETG Anti-Static KPA773

- Styrene in White, Black, or Conductive Black

- PP – Prime-COPP-792 Natural Off White

- PE – Polyethylene Natural Off White or Black

- Polycarbonate Clear or Black

- ABS Black