Electronics Parts Trays

ECP has extensive experience developing, prototyping, and producing ESD safe trays for packaging circuit boards and components requiring ESD safe protection. Stock tray options include 100’s of ESD safe packaging trays with no tooling cost. Custom tray options range from single cavity trays or ESD Safe clamshells for individual circuit boards to multi-cavity ESD trays with covers. Custom tray tooling can be low cost for lower volume applications. Contact a customer service specialist for stock tray information, sample trays, or to review a custom electronic component tray packaging option.

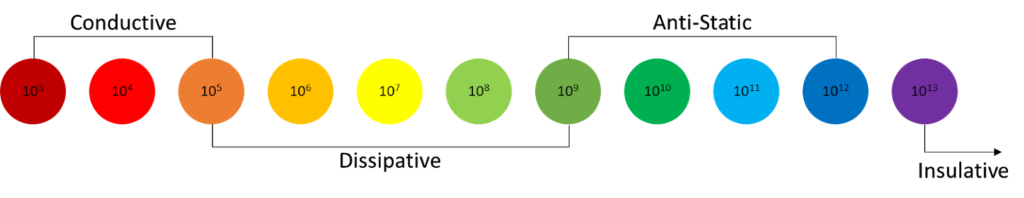

Ohms per Square chart was supplied courtesy of IPF Integrated Packaging Inc. This is a general guide to the levels of ESD material. Not all materials work for all applications and customer needs to specify requirements. Some common material technical data pages are noted at the bottom of this page for reference. A customer service specialist can assist you in choosing the correct material for your application.

Stock ESD Trays

Custom ESD Trays

STOCK Electronic Parts ESD Shipping Trays

Trays are either stock or standard. Stock trays are available in 1-2 days. Standard ESD Trays are available in 2-5 weeks run to order with no tooling with 100’s of cavity sizes available to choose from. Key considerations in choosing the proper EDS Tray include Material Type and Surface Resistivity. Common materials available are shown at bottom of this page along with links to data pages. By replacing ESD bags with ESD plastic trays, large time savings are possible from reduced component handling.

ESD Trays (PRODUCTS)

- Small Cavity ESD Shipping Trays – Stock in conductive black HIPS and Anti-Static PVC Clear.

- Anti-Static Plastic Shipping Trays – Run to order in 4-5 Weeks. Material Anti-Static Styrene.

- Clear Anti-Static Plastic Trays – Stock in Clear Anti-Static Material.

- Conductive Reusable Storage Trays – 1-2 Weeks. Made of thick conductive styrene.

ESD Bins (PRODUCTS)

- ESD OFF THE SHELF Divider Bins – Stock bins ship in 1-2 days in Conductive Black Polyethylene.

- Bins are permanently conductive; and have conductive lid options, conductive dividers, and conductive label holders for easy idetntification.

- ESD Bins are a relatively inexpensive way to store ESD sensitive parts vs. a custom ESD reusable tray.

- Multiple sizes and depths are Off the Shelf.

- Custom ESD inserts available for the bins including Custom Cavity Foam ESD Insert trays(NRE $ 95), and Custom ESD Plastic Trays.

- Contact Us for pricing on off the shelf items, for a custom insert tray quote, or for a recommendation on divider set up in based on your part.

- If off the shelf doesn’t work for your application, Custom ESD Bins are available at reasonable tooling and quantity.

CUSTOM Electronic Parts ESD Trays

Custom Formed ESD Trays: Protection

Safeguarding sensitive electronic components from electrostatic discharge (ESD) is paramount. Off-the-shelf solutions often fall short, which is where custom formed ESD trays add value. Whether you require thermoformed, vacuum formed, or specialty ESD solutions, customization offers unparalleled protection and efficiency.

– Thermoformed & Vacuum Formed Conductive Trays: These trays provide precise fit and protection, ensuring your delicate components are held securely and shielded from ESD. Their adaptability makes them ideal for various applications.– Anti-Static Trays: Designed to dissipate static electricity, these trays prevent damage to sensitive parts during storage and transport.

Specialty ESD Items:– Reusable Thermoformed Trays: Sustainable and cost-effective, these trays are built for repeated use, reducing waste.– Conductive Corrugated Fabrications: For larger or irregularly shaped items, conductive corrugated materials offer robust protection.– Kitting Trays: Streamline your production process with custom kitting trays, organizing components for efficient assembly.– Hinged ESD Boxes: Secure and convenient, hinged ESD boxes provide easy access while keeping components safe from ESD.

Benefits of Customization:

– Precise Fit: Tailored to your specific components, eliminating movement and potential damage, allowing clearance for sensitive areas.– Enhanced Protection: Conductive and anti-static materials ensure reliable ESD protection.– Improved Efficiency: Custom designs optimize storage and handling reducing required space for storage and manufacturing. Reduces handling time associated with esd bags.– Cost-Effectiveness: Reusable options and optimized designs can lead to long-term cost savings.

When selecting custom ESD trays, consider:

– Material: Conductive or anti-static properties.– Shape and Size: Tailored to your components.– Durability: Reusable or single-use options.– Specialty Needs: Kitting, hinged boxes, or corrugated fabrications.– Invest in custom formed ESD trays to ensure the safety and longevity of your valuable electronic components.

Keywords: ESD trays, custom ESD trays, thermoformed ESD trays, vacuum formed ESD trays, anti-static trays, conductive trays, reusable ESD trays, conductive corrugated fabrications, kitting trays, hinged ESD boxes.

Design Features: 1) Stack features, 2) finger clearance for easy access of trays, 3) Engraving (part numbers, website, or company name)

Custom Tray Material Options

Materials commonly used for ESD trays are noted at bottom of this page. They are split into ESD shipping materials and ESD reusable materials. Thermoformed plastic sheet can be topically coated, inherently dissipative, or conductive. Each style of ESD-protective material has different advantages and disadvantages. We can guide you to proper material choice but it is ultimately the customer’s responsibility to choose the material. We can supply samples throughout the process for evaluation and testing.

Custom ESD Tray Tooling

Custom Thermoformed ESD Safe Trays can be designed with low cost tooling. Tooling cost starts at $ 1,500 for a small tray with basic cavities and will increase based on complexity and overall size of tray. For a lower tool cost ask about our ESD custom foam cavity trays with NRE at $ 95.

Timing

Timing for custom trays depends on a number of factors. Smaller thin gauge Anti-Static shipping tray applications usually fall in the 4-6 week range. Heavier gauge reusable trays can be 6-12 weeks depending on complexity.

To learn more about our ESD protective packaging, visit our page Custom Thermoformed Tray Design Guide.

Common Materials for Shipping

PVC AS H1X – Anti-Static PVC clear coated 2 sides.

Conductive Styrene – KP Brand HIPS Black Conductive.

PETG_ESD IPF – PETG Clear Anti-Static extended shelf life.

PETG AS KPA – PETG Clear Coated 2 sides.

Reusable ESD Materials

Royalite_R63 – ABS Conductive.

HDPE ESD Guide – Guide for ESD Options. Applies to “Plastic Bins with Dividers” and some heavy duty plastic trays.

HDPE 250 – Standard data page for HDPE (not anti-static).

Data Pages

DISCLAIMER: This information is presented from the source manufacturer and is deemed to be reliable. However it is intended as a guideline. It is the sole responsibility of each buyer to make their own independent tests and decisions about whether any of these plastics are suitable for their packaging solution prior to purchasing. Product samples are available for review.

Relevant Electronic Industry Links

- Global Standards for the Microelectronics Industry: https://www.jedec.org/

- ESD Association: https://www.esda.org/standards/

- ECP JEDEC sized thermoformed disposable shipping trays