Home / Products / Foam Trays / Foam Material Information

Foam Material Information

Foam Tray Material Information For Cavity Trays

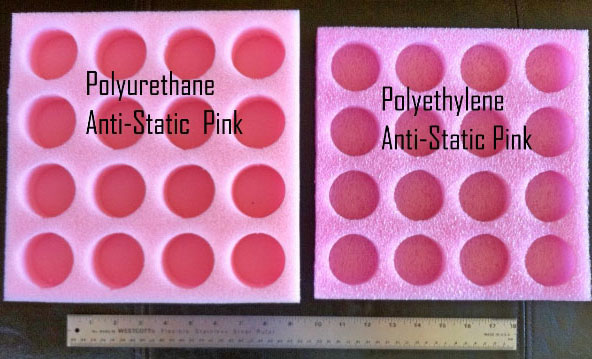

- Anti-static Foams (FIRST PHOTO TO RIGHT)

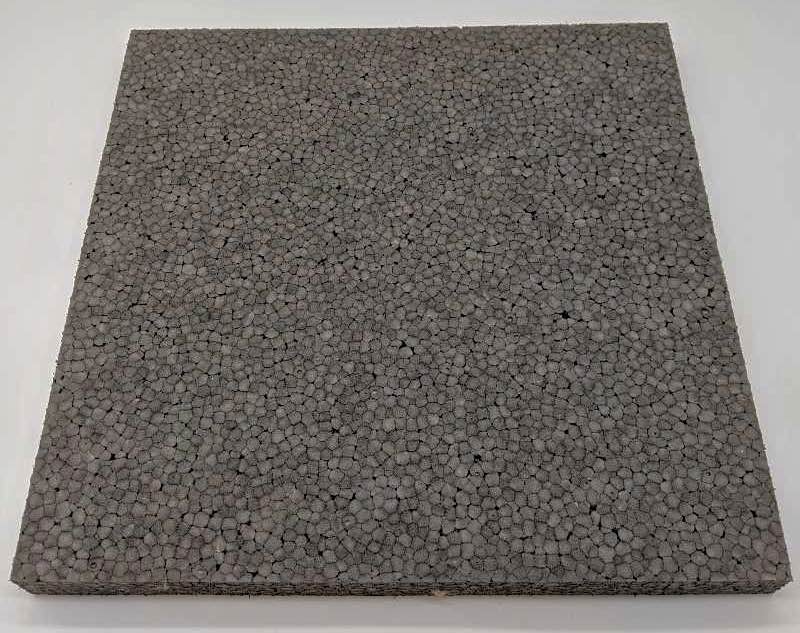

- Beaded PE or EPE. (THIRD & FOURTH PHOTO TO RIGHT) Rated for Class A finishes.

- Polyethylene foam (FIRST PHOTO COMPARISON)

- Polyurethane foam (FIRST PHOTO COMPARISON)

- Conductive foam including crosslink polyethylene foam (FIFTH PHOTO TO RIGHT)

Foam Materials for Stock & Custom Trays

- ANTI-STATIC: 1.7#, 2.0#, 2.2# Polylam Pink AS(anti-static polyethylene foam): These material can be cut to thickness and then die cut into a foam tray. It can be laminated to a thinner piece of ESD foam or to a piece of plastic corrugated.

- LEAST EXPENSIVE: 1.7# PE Black or 2450GY Polyester: The polyethylene PE foam material is has excellent characteristics for trays. Its unique color can differentiate the trays from separate departments or for different stages in your manufacturing process.

- MOST POPULAR: 1.7# Black Polylam Polyethylene foam: Inexpensive and durable material. This can be die cut into a separator or a grey foam tray. Lamination can be to plastic corrugated, or another piece of foam.

- DENSITY RANGE: Extruded PE foams in white, charcoal and black from 1.2# up to 9#. Polyurethane Foams, and PolyEster foams also stock for trays in white and charcoal including FR Polyester foam materials, and rubber.

- CONDUCTIVE FOAM: Conductive Foams are typically black in color.

- NON ABRASIVE FOAM: EPE or EPP Beaded Foam is a expanded polyethylene. Main advantage of beaded foam is that it is non abrasive material and can be used on class A surfaces. Expanded polyethylene is better than both urethane and polyethylene for painted metal or other parts requiring a non abrasive tray surface. Available in black in white 1.3#, 1.5#, 1.9#, 2.3#, and 2.8#. Second advantage is that it handles more impact and weight than a standard polyethylene so a less expensive density can be used.