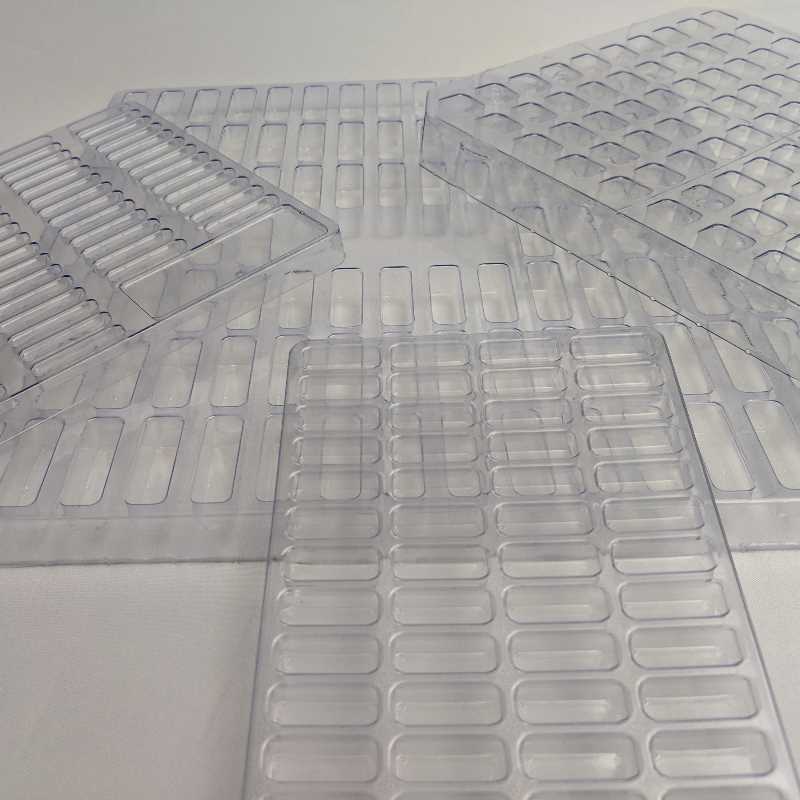

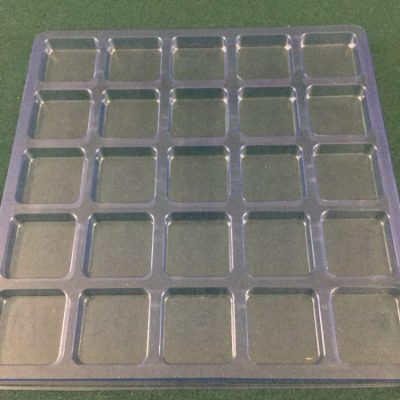

Description

Custom Made Shipping Trays are made with relatively low tooling costs. Tooling can be as low as $ 1000; and increases with size and complexity.

FEATURES:

- Cavity can be a variety of shapes to protect part.

- Lids can be used

- Stacking options

- Finger access can be designed into the tray

- Logos or part numbers can be molded into tray

- Custom cavity size

MATERIALS:

- ESD Materials including PETG, Conductive HIPS, Anti-Static PVC

- PETG for low outgassing

- PVC for low cost

- Styrene for low cost and with no topical coating; often used for medical trays

- PP = polypropylene

- HMWPE = High Molecular Weight Polyethylene

- Polycarbonate for higher heat applications. ESD polycarbonate available